Molten Sulphur Filters

Product Details:

- Product Type Molten Sulphur Filters

- General Use Industrial

- Material Stainless Steel

- Feature High Efficiency High Insulation

- Color Silver

X

Molten Sulphur Filters Price And Quantity

- 5 Set

Molten Sulphur Filters Product Specifications

- High Efficiency High Insulation

- Stainless Steel

- Molten Sulphur Filters

- Silver

- Industrial

Molten Sulphur Filters Trade Information

- Navi Mumbai - Maharashtra

- Cheque

- 200 Set Per Month

- 30 Days

- Yes

- Contact us for information regarding our sample policy

- Standard Packaging

- Australia North America Eastern Europe Middle East Western Europe Africa Central America South America Asia

- Maharashtra All India

- ISO 9001-2008

Product Description

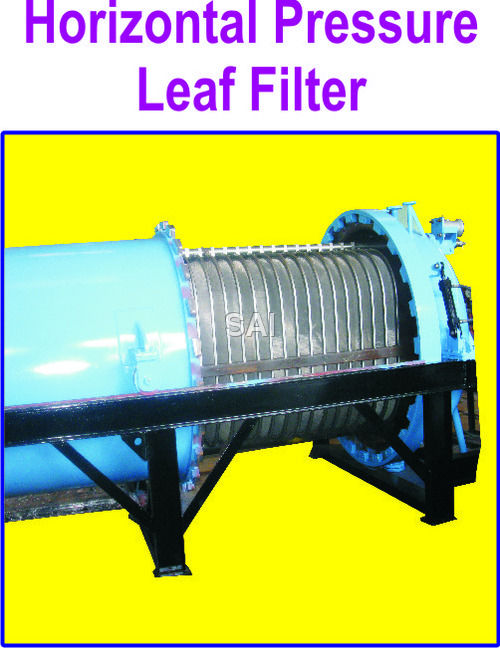

Molten Sulphur Filters

With our sheer motive to manufacture, export and supply an impeccable quality array of Molten Sulphur Filters, we have set up an advanced manufacturing unit. Suitable for filtering solid matter or ash occurred during the manufacturing process of sulphuric acid, these filters are widely used in sulphuric acid plants. Available in various models and material of construction as per the application requirements, our Molten Sulphur Filters are manufactured by using high grade material.

Features

- Easy to use

- Low on maintenance

- High on efficiency

Molten Sulphur Filters

- Need: While manufacturing Sulphuric Acid from elemental sulphur through acid manufacturing process as well as Chamber & contact, sulphur is burned at high temperature and leaves a residue called sulphur Di-oxide. In this process, presence of solid matter or ash can create high problem in acid plant, here molter sulpheric filters find their usage. Basic purpose behind using these is to remove all those particles that can create problem in suplhur production.

- Characteristic of Molten Sulphur: Molten sulphur, which is obtained from sulphuric acid has high freezing point and peculiar viscosity, which makes it difficult to handle. When the temperature of molten sulphur is increased from its melting point (110) to 157 Deg C then its Viscosity heavily decreases and then further increase with the temperature. For having constant temperature of molten sulphur during filteration process, all the valves & lines and filteration equipment are steam jacketed.

- Operating Data: Temperature: 140 - 145 Deg C

- -Flow: 2.5 - 3 Tons / M2 / Day.

- -(Depending upon quality of Sulphur Being Filtered)

- Equipment Type: The Jacketed Horizontal Pressure Leaf Filter

- Classification: As per the use for cleaning, these filters are divided in two types that are:

- Shell Retraction:

- Leaf Bundle Retraction:

- Filtration Area Available

- Shell Retraction (Hydraulic): 5 - 150 M2

- Leaf Bundle Retraction (Mechanical) : 100 - 300 M2

- Leaf Bundle Retraction (Hydraulic) : 5 - 150 M2

- Material of Construction

- Filter Shell: - SA 516 Gr. 60/70

- Filter Leaf: - SS 316 / SS316L / SS 904

- Jacket Shell: - SA 516 Gr. 60/70 / IS 2062.

- Leaf Construction

- 5 Ply

- 4 x 4 Mesh/14 SWG Drainage Mesh

- 8 x 8 Mesh/22 SWG Support Mesh

- 24 x 110 Single Plain Dutch Weave Filter Mesh

- Tubular Section, Fork & Nut Bolt, Mesh support mesh Nozzle and Washers

- 3 Ply: - 24 x 110 Single Plain Dutch Weave Filter Mesh

- Tubular Section, Fork & Nut Bolt, Mesh support mesh Nozzle and Washers

- Rigidrain - Open Size 6 mm x 6 mm x 3.15

- While reforming, the bolted design of these filters allow them to easily remove the damaged fine mesh.

We are holding expertise in supply / recondition of filter leafs for any make and any size.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Horizontal Pressure Leaf Filters ' category

|

SAI ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |