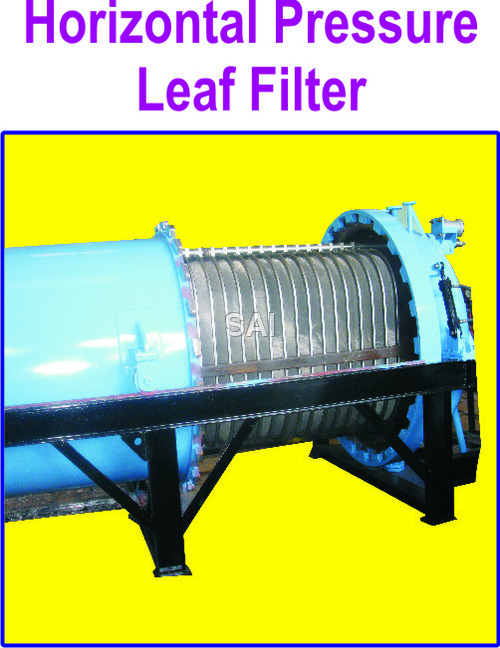

Horizontal Metal Leaf Filter

Product Details:

- Product Type Horizontal Metal Leaf Filter

- Material Stainless Steel

- Type Metal Leaf Filter

- Feature High Efficiency

- Color Blue

Horizontal Metal Leaf Filter Price And Quantity

- 5 Set

Horizontal Metal Leaf Filter Product Specifications

- High Efficiency

- Horizontal Metal Leaf Filter

- Metal Leaf Filter

- Stainless Steel

- Blue

Horizontal Metal Leaf Filter Trade Information

- Navi Mumbai - Maharashtra

- Cheque

- 200 Set Per Month

- 30 Days

- Yes

- Contact us for information regarding our sample policy

- Standard Packaging

- Australia North America Eastern Europe Africa Western Europe Middle East South America Asia Central America

- Maharashtra All India

- ISO 9001-2008

Product Description

We are a leader in manufacturing and exporting a versatile & sophisticated range of Horizontal Pressure Leaf Filter, which are extensively demanded in various chemical and solvent industries. Available in various models and specifications as per the specific requirements of clients, these filters are mostly designed using excellent quality materials. Our Horizontal Pressure Leaf Filter is highly demanded in the market for various applications such as dewaxing of edible oils, liquid glucose, fine chemicals and copper electrolyte solutions.

Features

- Perfect for low solid & high volume filtration

- Clear filtration

- Rigid construction

Horizontal Pressure Leaf Filter

Classification: Horizontal Pressure Leaf Filter are classified into two types as per their cleaning performance, details of these are:

Shell Retraction: This type of Horizontal Leaf Filter are built from Horizontal Cylindrical vessel along with special viton seal and bayonet wedged lock closure. On the 4 external wheel assemblies, retractable filter shell of these is mounted and the complete process of retraction gets complete by hydraulic cylinder. These also have mounted sensitive nozzles on fixed dish and during the cleaning process, there is no need to disconnect any piping while using leaf filters. To make it simple to open & close wedge lock, this type of filter has 2 Nos. powerful hydraulic cylinders that are linked with hydraulic power pack. On the central outlet manifold & clamped, with top common shaft for fixing leafs, 5 ply filter leaves are built from SS 316 L / SS 316 with mounting bottom drain nozzles. After the completion of filtration process with use of these, the filter is well drained & then left filtered cake is dried with the help of steam. Further, by scrapping after the shell retraction, dried cake is dislodged manually.

Leaf Bundle Retraction: It is built by assembling stationary horizontal cylindrical vessel with silicon seal & special bayonet wedged lock closure. With the end bundle backed by another set of rollers, this type of filter moves on rollers riding on tracks. for making the user have ease in opening and closing the wedge lock, leaf bundle retraction filter has 2 powerful hydraulic cylinders that are linked with connected with hydraulic power pack filter leaves that are made as per AISI SS 316 L standards with mounting bottom drain nozzles on central outlet manifold and clamped with the top common shaft for fixing leafs. These filters are generally drained after accomplishment of the filtration process. Next thing which is done is that the filter is opened and the cake is dislodged manually by scrapping method after retraction of Leaf Bundle.

Filter media - It contains a complete set of 5 ply leaves including two supporting mesh, two fine filter meshes and drainage mesh, revitted or bolted, fine filter media as per the SS 316 L.

Filter leafs are enveloped with the use of micron rating filter cloth & material when there is the need of lower micron rating.

- To have clear filtration results, (As needed), filter media is pre-coated with Diatomite earth / filter aid

- Cake Drying- Residue/cake which is left after filtration is dried with the use of N2, air & dry steam and the dried cake is then discharged directly with the aid of vibrator or it can also be manually scrapped off and collected in the hopper/ tray.

- On the fixed head of filter vessel, all the nozzle connections are mounted of these. While opening or closing the filter vessel during the process of cake discharge, make sure that no connections are disconnected.

- Shell Retraction (Hydraulic): 1 M2 to 150 M2

- Leaf Bundle Retraction (Mechanical): 150 M2 to 300 M2

- Leaf Bundle Retraction (Hydraulic): 1 M2 to 150 M2

- Available MOC - IS 2062, SS 304, SS 316, SA 516 Gr. - 60/70, and SS 316

- End Users - HPLF are widely used for filtering low solid and High volume filteration

- Liquid Glucose

- Dewaxing of Edible Oils

- Molten Sulphur

- Fine Chemicals

- Copper Electrolyte Solutions

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Horizontal Pressure Leaf Filters ' category

|

SAI ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |